Secure Set spray foam helps keep military jets safe

The US military recently conducted a series of tests designed to increase the ability of fighter jets to evade air-to-air and surface-to-air missiles. Secure Set Spray Foam, one of GRA Service’s most popular products, played an integral role in making these tests a success.

What is Secure Set spray foam?

Secure Set is a fast-setting expanding foam that is used to set utility poles in the ground. In its spray form, it had successfully been used, prior to the military test, to fill a void under a concrete slab. Eighty minutes after the void was filled, an 11,000-pound truck was driven over the slab, which remained perfectly steady and level. The polyurethane foam ensures stability through its high density and also forms an extremely powerful bond with any material on which it is used. It is designed to support 5,640 pounds per square foot. Although it was intended for use in the utilities industry, it has proven to be effective far outside of its original domain.

How does Secure Set spray foam help to keep military jets safe

The military division that ultimately came to GRA Services for help with their tests was charged with improving the safety and evasion capabilities of military aircraft. To do so, they built an enclosed chamber measuring 40ft in length by 15ft in width and 10ft in height. Inside the chamber, they fired off test flares and captured the relevant data. These flares are the ones that military aircraft use as decoys to throw enemy missiles off course. For the tests to be accurate, the chamber had to be completely sealed and airtight, forming a vacuum on the inside.

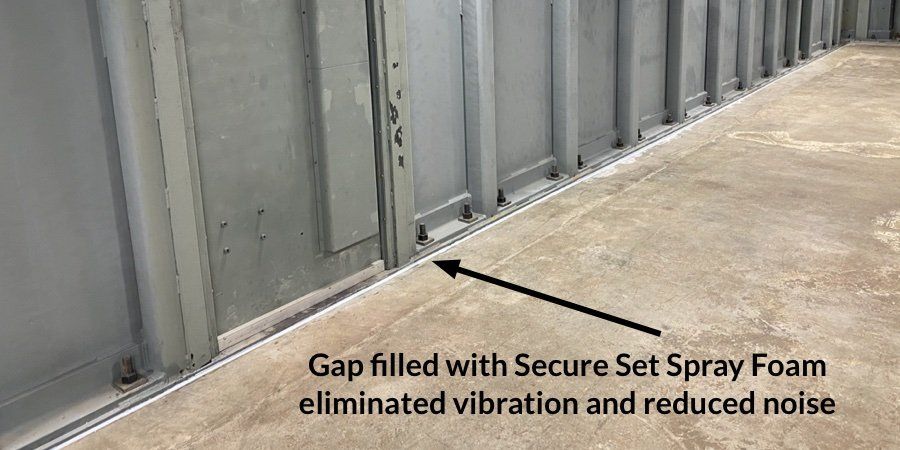

When the crew first performed the tests, they found that the results showed more variability than expected, suggesting that the test facility itself was causing inaccurate measurements. On inspecting the chamber, they found that there was a gap between the steel enclosure and the concrete floor, ranging from ⅛” to ⅝”. While the chamber was airtight, the gap under the chamber created unwanted vibration.

This meant that the tests were not being performed in perfect conditions, and a solution was needed to seal up the gap. After doing some research, the crew discovered GRA Services and SecureSet. In particular, they found the YouTube video demonstrating the void-fill application described above, which convinced them that the product could be the perfect solution.

They contacted the company, and Doug Reeves, GRA Services’ expansion foam expert, told them he was confident that Secure Set would do the trick. He outlined an improvised solution for applying the product, which involved the use of rubber tubing to get the foam into the gap. He also explained that the foam would form a powerful bond between the concrete and the steel, forming a solid joint that would be certain to remove vibration.

The use of Secure Set enabled the tests to proceed successfully, without the need to move or rebuild the facility. The team confirmed that Secure Set removed all vibration and also noted an unexpected benefit: ambient noise in the test facility was also reduced. They were able to collect all the data they needed on military jet safety. SecureSet offered a cost-saving and effective way for the tests to go forward to completion. In this way, GRA Services made a small but significant contribution to the military’s efforts to keep its jets safe.

For more information on Secure Set spray foam and GRA Services’ other solutions,

contact us today.